Refrigeration Solutions

In alignment with our vision to supply the world’s F&B outlets, we want to control the level of quality of the solutions we provide to our partners and ensure they receive nothing but the absolute best.

With Brodan we have incorporated the most advanced of technology and have an in house R&D and engineering team to achieve our vision.

We strive for a corporation wide capability to reach unprecedented levels of business performance.

Brodan’s mission is to provide a growing range of refrigerated and ambient display case units and coldrooms that are made according to industry owned standard.

Brodan is part of Vision 2030

The program is mandated to transform the Kingdom of Saudi Arabia into a leading industrial powerhouse...

get in touch

If you're looking for a reliable partner for your new project, please fill in the form below, and we will get in touch immediately.

Sign up to our newsletter today

Do you want to receive helpful tips for restaurant owners and managers?

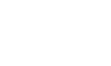

Display Refrigeration

Brodan’s mission is to provide a growing range of refrigerated and ambient display case units and coldrooms that are made according to industry owned standard.

Brodan is all about innovation. Our sole purpose is to work with our customers and interpret their needs to understand their challenges, opportunities and concerns.

Applying this knowledge and unleashing the power of the R&D branch of Brodan, we have come out with the Souda line of display cases and Grab and Go, built and assembled in our factory in Saudi Arabia.

Souda Grab & Go

Brodan’s mission is to provide a growing range of refrigerated and ambient display case units and coldrooms that are made according to industry owned standard.

Souda Ambient

Brodan’s mission is to provide a growing range of refrigerated and ambient display case units and coldrooms that are made according to industry owned standard.

- Features

- Specification

- Downloads

Sanitation:

Sanitation:

- The interiors have unions with curved edges (wide radii that facilitate cleaning) according to DC 89/392 and approved by Royal Decree 1435/1992, RD 56/1995. Adjustable legs in height (200mm) to facilitate the cleaning of the floor and the stability of the equipment.

- 100 mm sanitary back cover on countertops.

- Easy disassembly of grills and guides for a correct cleaning of the interior of the equipment.

- Drain inside the equipment for the evacuation of cleaning liquids or for breakage of any container. Possibility of connection to sanitation network.

Structure:

- Polyurethane insulation injected at high pressure free of CFC’s with density 40 Kg / m3.

- Exterior and Interior in Stainless Steel AISI 304 (roof, bottom, back, sides, front and back doors). Worktops in AISI 304 steel.

Doors:

- Doors equipped with hinges for automatic return and permanent pressure during closing. The automatic return is free when the opening exceeds 95º.

- Throttled door with three-chamber easy-to-replace weatherstrip.

- The quality of the weatherstrip material (free of lead and cadmium) ensures its stability against fatty acids, yeasts and fungi.

- The new, double grip handle is integrated in the same door with great strength. In all low furniture you can change the direction of the doors.

Control systems:

- Use of digital controllers and integrated control panel protected against grease and liquids. The degree of protection against liquids is classified as IP44, while the digital controller reaches IP65 degree.

- Greater precision in temperature control.

Easier to adjust the temperature range we want to achieve. - BGood visualization of the temperature and of all the processes through a digital screen.

- Remote alarm signal.

The temperature probes are NTC type encapsulated and sealed, responsible for controlling the temperature of the chamber and the end of defrosting.

Refrigerator system:

- Ventilated Condensation System that allows a quick and efficient exchange of temperatures in the unit that results in better equipment performance.

- The constant circulation of air prevents the accumulation of heat in the housing of the unit and ensures its cooling regardless of the location of the furniture.

- Extractable condensing units and use of evaporative trays in stainless steel.

- The low temperature equipment uses a hot gas defrost system.

- Use of forced draft evaporators that guarantee optimal performance and homogenizing the temperature inside the equipment.

- Use of anticorrosion treated evaporators.

- Use of compact Monoblocks (INFRIBLOCK) increasing the capacity of the chamber, improving its cleaning, and also facilitating the maintenance of the equipment.

Technical Specifications:

Panel Insulation: CFC Free, Rigid Injected Polyurethane Foam. Panels are specially made in Italy.

Warranty Period

Write a short description, that will describe the title or something informational and useful.

Energy Efficiency

Write a short description, that will describe the title or something informational and useful.

Components

Write a short description, that will describe the title or something informational and useful.

After Sales Service

Write a short description, that will describe the title or something informational and useful.

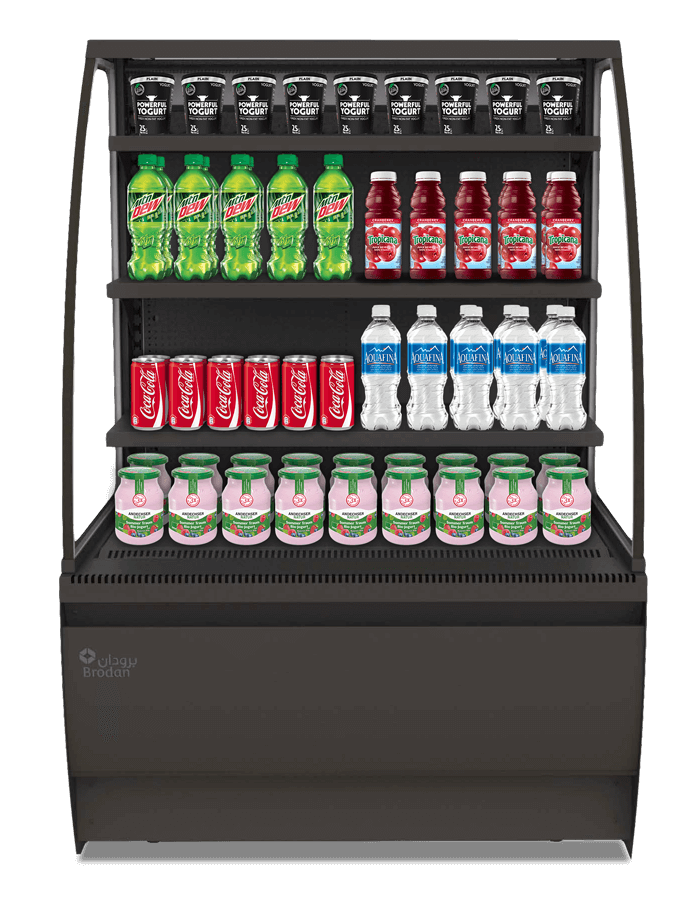

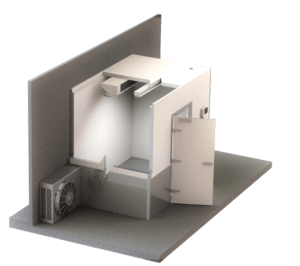

Coldroom Solutions

In the restaurant business the storage of chilled or frozen products has always been a challenge of sorts. We understand its importance and have worked to be able to find a solution in our cold storage products that fit every need and can be customised to fit any kitchen dimension.

Brodan 3G system is designed with three principles in mind: top quality, solid operation and energy saving. Basically, it was designed putting the customer first. Customized production to cover the clients specific requirements, the result is the smartest and most economical

Chiller-Freezer rooms in the Kingdom and we are proud to be manufacturing in its entirety in Saudi Arabia.

Energy Efficiency

We have invested significant time and resources assessing the energy efficiency of cold and freezer rooms. On the back of this research we have designed our third generation panel which offer great value with no additional cost and great saving in energy and operation.

Easy Accessibility

Our doors provide the ability to wheel items directly into the cold room without the need for a cabinet door to be held. Both swing and sliding doors combine the latest technology, premium materials and design features to meet the demanding requirements of the cold storage industry.

Size Flexibility

Our cold rooms can be professionally customized to fit your place. Either you have a big or small area, we mostly can design the cold rooms based on your dementations. When you compare this with a fridge or freezer of similar capacity, not only does it offer more space but also flexibility

Low Price

It is a common myth that cold rooms are expensive. On the contrary, large cold rooms way cheaper than buying multiple double-door upright commercial refrigerators. A cold room with size of 2m x 2m x 2m allowed more than 7000 litre which costs you around SAR 30,000, while double-door commercial refrigerators with the same capacity will cost more than SAR 70,000.

-

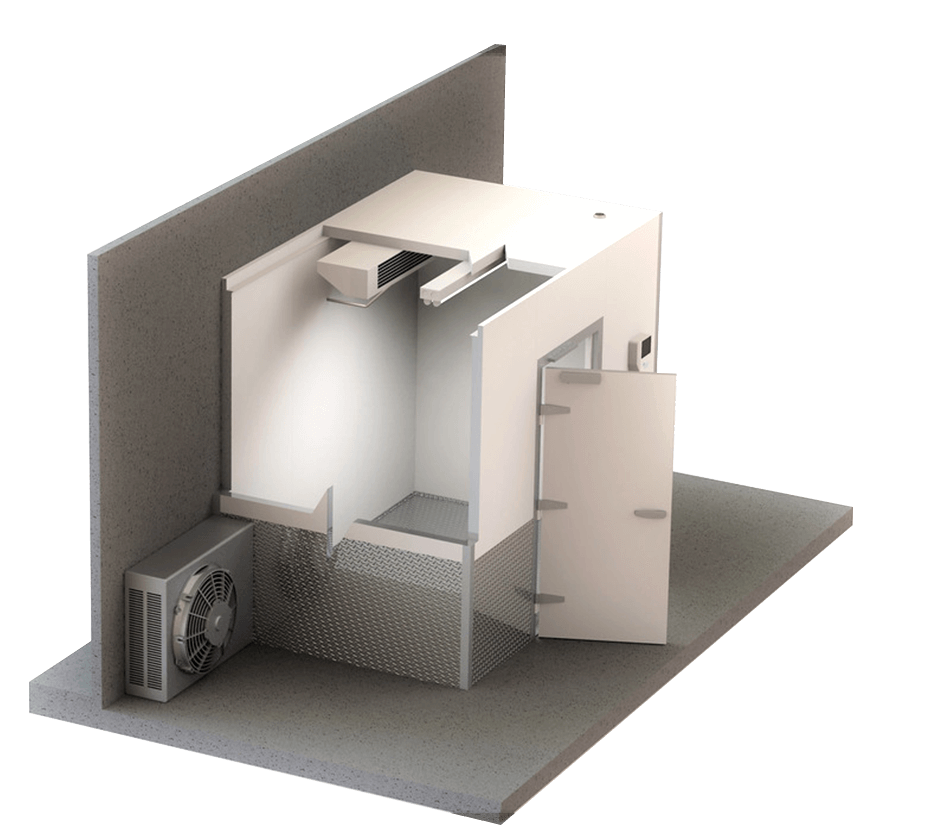

Monoblock System

Monoblock System -

Monoblock System

Monoblock System -

Remote Unit System

Remote Unit System

Examples

- Features

- Specification

- Downloads

Flush Mount Refrigeration Package: This new design element eliminated the space occupied earlier by an evaporator and allowed for the entire interior to be used for storage.

Baro-Flex® Swing Doors: The third generation doors has drastically improved. It is recessed, automatic self-close, with triple self-raise hinges. Therefore, the recess door frame design coupled with the automatic closer, extremely reduces thermal leak and reduces energy and service costs. The ergonomic door handle is designed to be pulled as the door doesn’t need to latch or lock. Basically the door doesn’t need to be handled when closing.

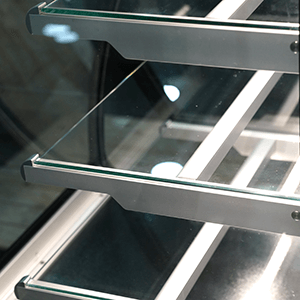

LongWall® Panel: The third generation panel is uniquely designed to offer great value with no additional cost and great saving in energy and operation. The new standard overlapping joint design helped achieve two important elements: 1) higher thermal insulation with added mechanical strength to the room. 2) Increased aesthetic value and hygiene as there is no need to finish joints with silicon with virtual absence of seams between panels. The panel continues to have the dual effect camlocks and the sanitary microribbing and other great features in older models.

Monolithic Coving: Hygienic Angle bar coving system that facilitate cleaning and reduces the accumulation of dirt.

System Controls: Compact and smart looking Dual/Single room controls with no exposed wiring and with temperature alarm. Controls come with optional feature of remote temperature monitoring and controls.

Pressure Relief Valve (Freezer): Standard to all freezer rooms to insure pressure balance.

Panel Insulation:

CFC Free, Rigid Injected Polyurethane Foam. Panels are specially made in our KSA facility,

Density: 42 kg/m3.

Thickness: Ranges from standard 100mm but can custom designed from 80mm to 120mm, temp rating -22oC (80/100mm panels) to -30 and below (120mm panels),

Cladding: 06mm Pre-Coated anti scratch, Galvanized Steel Sheets with Antibacterial coating.(customized SS panels grade 316 available for specialist applications)

Fire Rating:

Meets redundancy requirements based on DIN 4102 class B3 and according to ASTM class B3 and ISO 3582. Construction: Panels are joined together + Cam-Lock system with water proof seal to ensure moisture resistance and ease of installation.

Doors:

All fittings including rubber gasket. Internal Safety Handles are to be standard white. As a safety measure the door handles illuminate from inside the room to help worker reach to handle immediately if the door suddenly closes and the lights go out. Swing door is using hydraulic self closing doors.

Lighting:

Heavy Duty, Water Proof, Low Energy Fluorescent Lighting T5.

Plastic Curtains:

Transparent strips are 200mm wide and 2mm thick.

Refrigerant: R-404 Electrical

Rating: 220/1ph and 380v/3ph (unless otherwise specified)